Growing wood in a lab

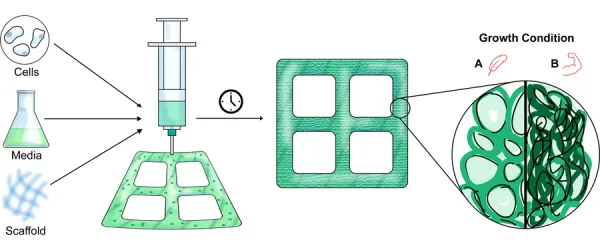

After the scientists cultivate the plant stem cells into the required quantities of wood, they place them in a printer where the cells act as “Printing inks” and they can instantly print products ranging from small wooden toys to large wooden furniture.

Image by MIT

MIT’s researchers claim that creating products made of wood in such a way Reduces wood wastage up to 30% (for example, if you use real wood for furniture. There will be pieces of wood that are cut off and become garbage, while using a 3D printer requires a fair volume of raw materials) Moreover, cell cultures grow much faster than planting trees. The important thing is that it can grow even in the place without any sunlight!!

Image by Lukas/Pexels

“The idea is that you can grow these plant materials in exactly the shape that you need, so you don’t need to do any subtractive manufacturing after the fact, which reduces the amount of energy and waste,” Beckwith said.

For now, scientists have been able to show that plant material can be grown in a lab and its mechanical properties can be manipulated, but the study is still in its early phase. More research and experiments are required to be done before the technique could be developed further and employed for producing 3D furniture in the lab on a commercial scale. These days, humans cut down 15 billion trees per year. With such a large number, it is even more severe global warming. Therefore, we hoped that this technology of Man-made Wood products will help us reduce deforestation in the future.

Currently, many countries around the world, such as the European Union, Japan and China, are adapting to a circular economy. in order to solve the resource crisis that occurred However, the adoption of this concept has not been very successful due to various obstacles and limitations such as consumer behavior that is not used to environmentally friendly goods and services or second-hand goods. The cost of adjusting the production process and the risks incurred from changing the business model including insufficient labor potential with advanced production technology.

Image by UN

For Thailand, the 20-Year National Strategic Plan (2017-2036) by Former PM. Prayut Chan-o-cha has formulated a strategy for building growth with an environmentally-friendly quality of life complied with the United Nations’ Sustainable Development Goal no.12 on Ensure Sustainable consumption and production plans. Thus, the Circular economy is the key to achieving this goal, however, the awareness of the circular economy has no certain evident in the Thai business sector.

Next Episode, we are going to introduce you guys, the SDGs activities at Daiwa Shiryo’s Japan head office.

Thank you for good data from https://www.tnnthailand.com/news/tech/115109/

Find out more (Japanese) on SDGs activities of our Japan head office