What is the recycled pulp? Recycled pulp or it can be well known as DIP (De-inked Pulp) because the de-inked unit plays a vital role in the recycling process.

There are many kinds of raw materials for recycling pulp processes such as OCC, kraft paper, office paper, milk carton, and so on.

What is the utilization of recycled pulp? Recycled pulp is used as a raw material for paper productions such as tissue, packaging box, newsprint, and printing paper. Moreover, it can be used as a compound for construction material including molding production.

Why must be recycled pulp? Of course, the price is cheaper than virgin pulp even though the quality is not comparable but it can be used for the products

that do not require very high quality. Additionally, the use of recycled pulp can save water and energy in the process, reduce waste which results in environmental pollution, and reserve the space for other waste which must require for landfills.

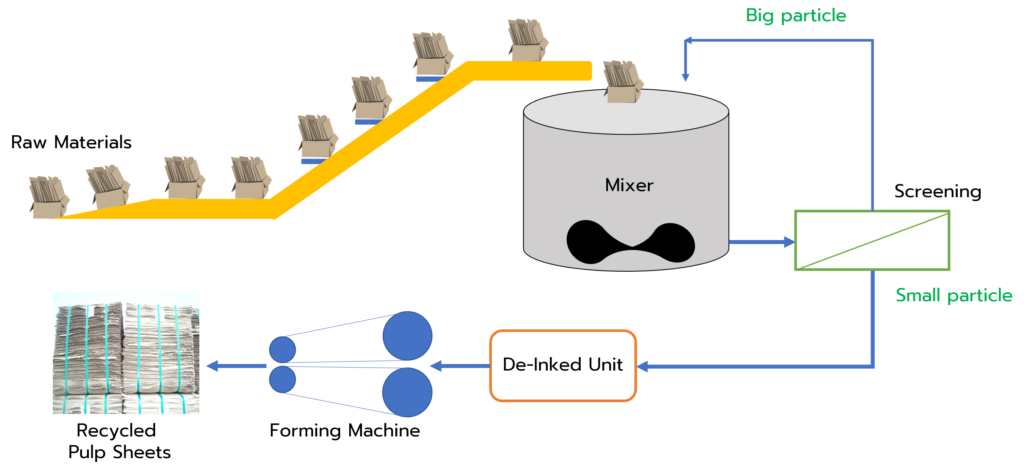

Daiwa Shiryo, our mother company located in Osaka, Japan also has a recycled pulp mill at Takatsuki city. This plant has a confidential document destruction service. Almost confidential document are office papers which can be used as raw material for recycled pulp. For recycled pulp process at Takatsuki plant is described

in Fig. 1.

Fig. 1 General process diagram for recycled pulp production based on Takatsuki Plant in Osaka

Raw materials are conveyed via a conveyor to the mixer tank and mixed with water and some chemicals using an agitator. This unit can be called as a pulper unit.

The pulper cuts the waste papers into small pieces. In this step, the waste paper becomes a pulpy fluid called pulp.

Pulp is transferred through screening. This process some contaminants such as plastics, metal, and so on are removed. Big particles are transferred to mixer again

in order to make them smaller. Small particles of pulp are fed to the de-inked unit.

The de-inked unit is using 2 principles; washing and floating. Pulp is cleaned by rinsing with water in a washing process. Some small ink particles are removed

in this stage. Meanwhiles, the bigger particles are removed by air bubbles in a floating process.

To make integrated pulps, pulps are compressed at forming machine and turn into the pulp sheets. Finally, the pulp sheets are cut into the specified size

and loaded on the pallets.

Daiwa Shiryo Japan can provide recycled pulp that is BKP-C-B for sale. The main raw material consists of confidential documents and cardboard. If you are interested in this product, please contact us for more information or drop us a message at sales@daiwashiryotrading.com